Waste To Energy Refining

GABRICH Refinery & Petrochemical Limited is engaging in the Pyrolysis Process of converting plastic Waste To Energy, and in the process of collaborating with Lokus Energy for the execution of the project and for Innovative Waste-to-Energy Project Income Generation Proposal.

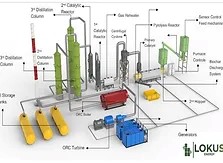

GABRICH WASTE TO ENERGY PLANT

PROCESSSING 100 TP/D MIXED WASTE TO PRODUCE 40,000 LITRES BIODIESEL DAILY

22 TONS CARBON CHAR PER DAY

196 M/3 BIOGAS PER DAY

12 TONS P/D BITUMEN

Lokus Energy has provided us with a formal proposal for the design, manufacturing, installation and commissioning of a Waste to Energy (WtE) plant to process all types of solid waste and biomass to produce liquid fuels as biodiesel and syngas as well as solid by-products. The proposal provided us with a background of Lokus Energy, the project summary, technical information and estimated production levels of fuels and other bi-products. It also includes cost, payment schedule and suggested delivery schedule.

Lokus Energy is engineering firm, that specialized in the Design, Manufacturing sustainable Waste-To-Energy plants with Gasification & Fast Pyrolysis technology, offering zero waste & zero emission performance with flexibility to process all types of mixed waste “MSW” & biomass into biodiesel, petrol, jet fuel, kerosene, hydrogen & syngas as well as solid by-products “Graphene”.

Lokus Energy Electrolyser technology is to produce Green Hydrogen with Hydrogen storage & distribution systems that have been delivered worldwide. The team have developed and patented their own hydrogen engine for cars & trucks that consists of 70% less parts/components, comparison with typical fuel-cell and combustion engine technology.

GABRICH Refinery & Petrochemical Limited Public-Private Partnership (PPP) project is undergoing through the feasibility study and establishment of funding agreement stage with foreign investment partners with GABRICH Refinery & Petrochemical Limited’s provision of 70 acres of land. This land allocation is pivotal for the establishment of diverse components essential for the millions of dollars project’s infrastructure, encompassing;

• The industrial-scale plant,

• A landfill,

• A technical garage,

• A training institute,

• And a buffer zone,

This zero emission biofuel technology facility aims to process 400 metric tonnes of assorted waste and biomass from the 36 states of Nigeria, yielding an array of energy products, including biodiesel, hydrogen, syngas, and solid by-products.

A team of the project facilitators is in-talks on moving the project forward.

OUR WASTE TO ENERGY REFINERY TARGETS

• Removing waste from landfill site that causing environmental hazards.

• Recycle waste & biomass with zero waste & zero emission plant performance.

• Producing energy from waste and many by-products.

• Creating jobs and income from waste.

• Offering sustainability in waste management practices and energy supplies.

• Decarbonisation of transportation sector, energy sector & manufacturing industry.

• Saving the environment & saving lives.

• Achieving ZERO to landfill targets and NET ZERO emission targets.

• Creating green jobs, introducing new technologies & income streams.

• Helping Government to deliver SDG goals for sustainability & circular economy

This million dollars project involves Lokus Energy team on one side, GABRICH Refinery & Petrochemical Limited, and its investment Partner for Financial Services as the special purpose vehicle implementing it.

Securing of Government approval is ongoing and documentation processes under review.

With reduced government capitation, GABRICH Refinery & Petrochemical Limited is keen on income generating investments to propel its growth ambitions. The project is also expected to boost GABRICH Refinery & Petrochemical Limited’s quest to establish a center of excellence in climate change action in collaboration with Lokus Energy as the buyer of 30% of the refined products. It is also expected and estimated to create at least 1,300 jobs at full capacity, with 400 of these permanent and pensionable, pushing the neighboring communities into a University and industrial town.

Waste and Energy Crisis;

Why have energy prices risen so high !!!

Fossil fuel based energy systems are highly polluted and expensive.

Energy supplies & security is the back bone of all countries. Current energy supplies are comprising mostly of fossil fuels and most of the countries like Nigeria are dependant of imported fossil fuel based energy which is not sustainable and suppliers can push the prices up or stop the energy supplies in the time of pandemic, natural disasters and war. A better options are available now.

In the recent decades’ waste conversion technologies has been improved to produce cleaner, sustainable, cost-effective energy from solid wastes & biomass which is either low-carbon liquid fuels “OR” zero-emission fuel “Hydrogen”. These technologies are tested & proven, available to deploy locally in Nigeria where the waste is produced “AND” where the energy supplies are needed. This is the right time to take control of energy supplies in own hand, recycle 100% of the waste locally and produce own energy to become less dependant on imported energy.

For further information;

Waste endangering the Marine life

One truck load of waste drops into the ocean every minute of the year.

More than 171 trillion pieces of plastic are now estimated to be floating in the world’s oceans, according to scientists.

Plastic kills fish and sea animals and takes hundreds of years to break down into less harmful materials.

The concentration of plastics in the oceans has increased from 16 trillion pieces in 2005, data suggests. It could nearly triple by 2040 if no action is taken, scientists warn. At present, nations signed the historic UN High Seas treaty aiming to protect 30% of the oceans.

More than 91% of overall waste is not recyclable. A perfect solution to the waste problems is conversion of the waste into renewable energy source, ideally into low carbon biofuels, syngas and zero-emission-fuel “hydrogen” with advanced pyrolysis & gasification technologies at the source where the waste is produced.

GABRICH Refinery & Petrochemical Limited has developed the most advanced method and technological solution on an industrial-scale to eliminate the waste problems in Nigeria to recycle 100% of the waste in an environmental manner. This particular plant technology offers a zero waste & zero emissions performance, thus it operates as a carbon reversal, carbon neutral technology to help governments & private sector to meet net zero targets, to achieve sustainable development goals, to create jobs & income in order to achieve sustainable economic growth.

2.1 Billion Tons Waste Every year

The one biggest problem around the world is the excessive amount of waste produced daily. Daily waste generation much higher than the industry can cope with, even the peak of waste generation in most countries has not reached yet. Peak of waste generation in the Asian countries might reach by 2050 and in African countries by 2070.

Currently, the whole world is producing 2.1 billion tons (2019 figure) of waste every year and it will reach 3.4 billion tons per year by 2035.

Municipalities are increasingly looking at new sustainable technologies, tools and processes to manage waste, so it does not pollute our environment, or endanger lives. Landfill sites resulting in the loss of potential income, energy and an opportunity to create jobs. Landfill sites are facing the capacity issue “OR” no longer available.

Landfill sites lead to a various problems such as;

• Pollution (methane) 26 times more dangerous than CO2.

• Bad Bacteria, virus, diseases.

• Contaminate ground waters and soil.

• Wastage of energy source, wastage of useful land, wastage of opportunity to invest and to generate new revenue income streams.

In less developed countries like Nigeria, waste often discarded on the side of roads, rivers and canals resulting in damage to the local population, animals and the environment. Waste delivered to the oceans with the rain waters, floods through canals and rivers, endangers the marine life.

GABRICH Refinery & Petrochemical Limited is set to provide an industrial-scale technological solution to recycle 100% of the waste in Nigeria and produce much needed, cleaner, cost-effective & sustainable energy from waste.

Our Programs;

Together with our technical project execution partner, we are playing a vital role building bridges in Nigeria, and guaranteeing the energy security through the disposal of wastes.

* To protect the environment & lives with carbon neutral technologies.

* To create jobs and income in support to the Nigeria economic growth.

* We Help the Nigeria Government to achieve sustainable development goals.

* To create a knowledge sharing network in Nigeria.

* And to consult Federal & Regional governments in policy framework.

* Our Waste To Energy Refining will be offering technologies to decarbonize transportation sector, energy sector, and manufacturing sector.

* And will help to achieve ZERO to landfill & NET ZERO targets.

* We will be creating well-paid, permanent green jobs & new income streams into the economy, and finally Help the Nigeria Government to deliver SDG goals to achieve sustainability, green growth and circular economy targets.

Empowering Communities:

At GABRICH Refinery & Petrochemical Limited, we believe in networking, knowledge transfer, is dedicated to creating a positive change by utilizing cutting-edge technologies and sustainable practices. We strive to lead the way towards a greener and cleaner future for the generations to come. We are creating positive impact in all continents.

Innovation & Exploration:

Young explorers of today are the innovators of tomorrow. We encourage curiosity and exploration to inspire the next generation of environmental leaders. Through educational initiatives and interactive programs, we aim to ignite a passion for sustainability and empower young minds to think creatively and proactively about environmental challenges. We will be offering apprenticeships, employ freshly graduated engineers & students and provide further training & education.

Mapping Sustainable Future:

We are mapping the world towards sustainable futures. Our comprehensive approach integrates advanced technologies with environmental stewardship to create a roadmap for a cleaner and more resilient planet. We are collaborating with global partners to chart a course towards sustainable development and a harmonious coexistence with nature. We will spend our resources to collect environmental data to calculate potential threats to the world in order to design technological solutions.

The Benefits of Waste to Energy

• Less dependant on landfill sites.

• Reducing pollution.

• Achieving 100% recycling targets.

• Creating wealth out of waste.

• Creating jobs.

• Production of greener,

• Cost-effective energy to achieve circularity & sustainability.

• Achieving NET ZERO targets with energy transition from fossil fuels to renewable energy.

• Reducing risks of disease, Vermin, viruses, bad bacteria.

• Saving the environment & lives.

Innovative Solutions for Sustainability

Industrial-scale plant has been developed with advanced biofuel technology to process all types of waste & biomass to produce various different types of energy products as biodiesel, petrol, jet fuel, kerosene, hydrogen, syngas and solid by-products.

The system has been designed to operate on full auto mode with a complete integration between major components to fix any possible issues itself at Ai to enhance the safety & security of the plant & operators.

Comparison Waste to Energy Technologies

None other waste to energy plant technologies offer zero waste & zero emission performance as GABRICH Refinery & Petrochemical Limited will be offering in collaboration with our Project Execution Technical Partner

None other plant technologies offer more than 42% efficiency rate, our technology offers minimum of 85% efficiency rate. Our Project Execution Technical Partner has developed decentralised, modular based units for smaller footprint and higher output. Faster and cost-effective solution. The technology will are bringing in Nigeria does not require PPA to operate.

Hydrogen Production & Supplies

Our Project Execution Technical Partner has developed hydrogen engine for cars & trucks. The hydrogen engine consists 70% less components comparison with typical fuel-cell engine technology or other combustion engine technologies. Thus, it is faster & cheaper to build and does not require pure hydrogen. Our Project Execution Technical Partner has manufactured and supplied Electrolysers with hydrogen storage & distribution systems for customers around the world. Our waste to energy plant will also be producing pure hydrogen from waste.

Feeds In Nigeria

It’s not yet 100% certain the quantity of plastic waste materials we can source per day, but we are sure that we can use local workforce to achieve from 50 to 200 tones per day nationwide. And the project will begin by setting up a waste dumping and collection site using local workforce. By the time the plants are fully ready for use, we have secured feeds that we can use for processing for one year and still gathering.

We are not seeking for any entity or government sectors to pay use for waste collections; rather we will have to pay both suppliers and local individual waste collectors. Hoping to get paid from waste collection will bring competition that will not only try to sabotage our goal but it would bring secret enemies and competition with companies that already getting paid for waste collection. We don’t want to do that. Another reason is that getting paid for waste collection means that we will be collecting every kinds of waste which will bring more responsibility of segregating and disposal of unwanted waste such as metals and woods. We don’t want to engage in such waste segregation. We want to concentrate strictly on general plastic waste collection and sourcing.

GABRICH Refinery & Petrochemical Limited, together with our Project Execution Technical Partner team of professional and competent personals, is ready to undertake the project regardless of its size or the type of the waste. Our waste to energy project is planned for the collection, sorting, reducing, recycling and turning waste into energy, construction and bio products. Power generation from all types of the waste materials for national grid in Nigeria which is one of the most desirable and major sector we are passionate about to develop.